As I sit upon my porcelain throne, I often ponder the inner workings of the humble toilet tank. How does it magically fill with water, ready to unleash its powerful flushing force?

Join me on a journey of exploration as we delve into the components that bring this marvel to life. From the water supply and fill valve to the intricate flushing mechanism, we will unravel the secrets of the flapper, float, and float valve.

Along the way, I will share maintenance and troubleshooting tips to ensure a smooth operation.

Let us embark on this fascinating quest to uncover the mysteries of how a toilet tank works.

Key Takeaways

- The components of a toilet tank include a porcelain or ceramic container, a flush valve, a fill valve, an overflow tube, and insulation.

- The water supply valve regulates the water flow into the tank, while the fill valve controls the amount of water that enters the tank.

- The flushing mechanism relies on water pressure control and a flapper valve to seal and release water into the bowl.

- Proper water pressure control, regular maintenance of the flapper valve, and understanding its function are essential for efficient flushing and water conservation.

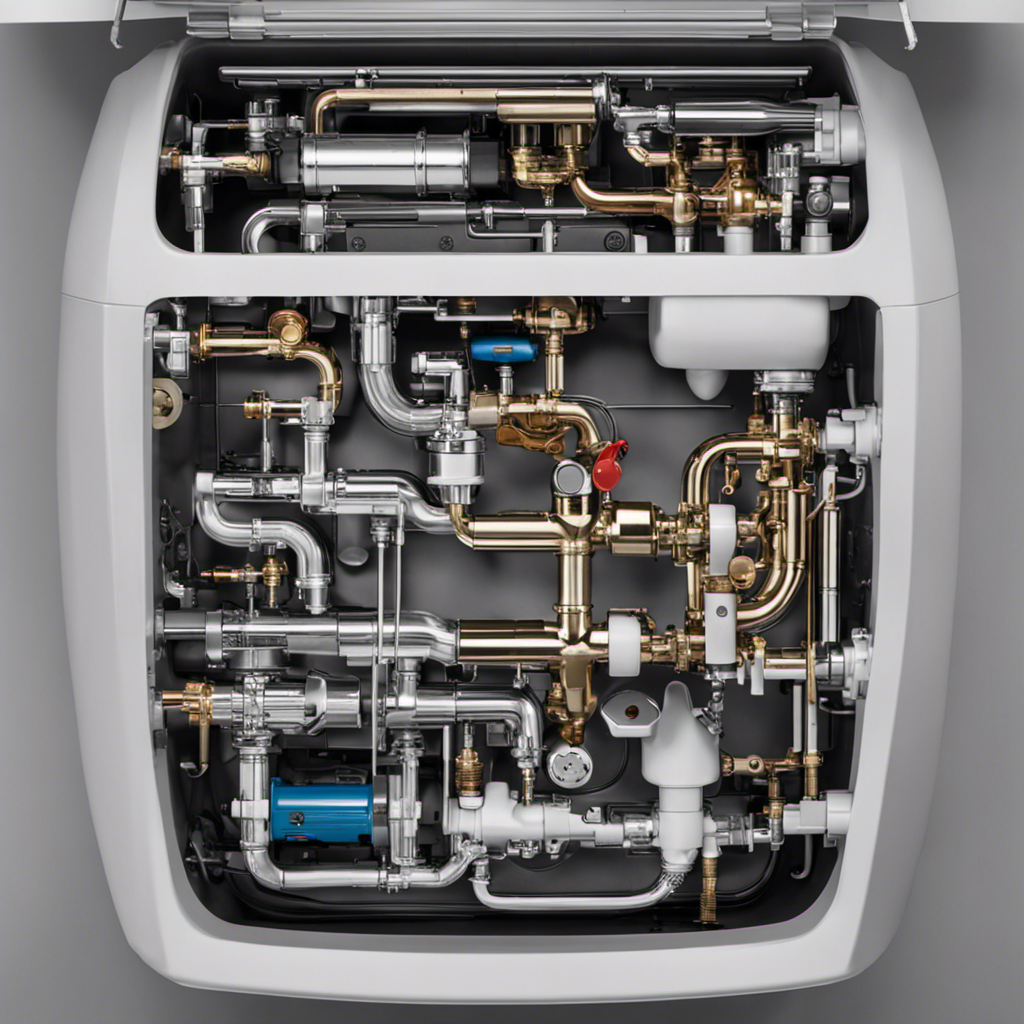

Components of a Toilet Tank

To understand how a toilet tank works, you need to know the components that make up its structure.

The construction of a toilet tank typically consists of a porcelain or ceramic container that holds water.

Inside the tank, you will find a flush valve, fill valve, and overflow tube.

The flush valve is responsible for releasing water into the toilet bowl when the flush lever is pressed.

The fill valve then refills the tank with fresh water after the flush.

Additionally, many modern toilet tanks are equipped with insulation to prevent condensation and keep the water temperature stable.

This insulation is usually made of foam or rubber lining that wraps around the tank, helping to conserve energy and reduce water waste.

Water Supply and Fill Valve

The water supply and fill valve play a crucial role in the functioning of a toilet tank. These components control the flow of water into the tank during the toilet’s operation. When it comes to toilet tank installation or repair, it is essential to understand how the water supply and fill valve work.

The water supply valve is typically located on the wall behind the toilet. It is responsible for regulating the water flow into the tank. By turning the valve clockwise, you can shut off the water supply in case of a leak or repair.

The fill valve, on the other hand, controls the amount of water that enters the tank after each flush. It automatically refills the tank to the desired level. If you notice any issues with the water level or filling process, it may indicate a problem with the fill valve.

Understanding the water supply and fill valve is essential for proper toilet tank installation and repair. Now, let’s move on to the next component: the flushing mechanism.

Flushing Mechanism

When it comes to the flushing mechanism of a toilet, there are several key points to consider.

First, water pressure control plays a crucial role in ensuring a powerful and efficient flush.

The flapper valve function, on the other hand, is responsible for sealing the water in the tank and releasing it into the bowl when the flush lever is activated.

Lastly, gravity-assisted flushing relies on the force of gravity to remove waste from the bowl, making it a reliable and low-maintenance option for toilet systems.

Water Pressure Control

Adjusting the water pressure control valve is crucial for regulating the flow of water into the toilet tank. This valve helps maintain the desired water level in the tank. Here are three key points to consider about the water pressure control:

-

Water Level Adjustment: By adjusting the valve, you can control how much water enters the tank after each flush. This allows you to customize the water level according to your preference and ensure efficient flushing.

-

Overflow Prevention: The water pressure control valve helps prevent the tank from overflowing by regulating the water flow. It ensures that the tank does not exceed its maximum capacity, avoiding any potential leaks or water damage.

-

Water Conservation: Properly adjusting the water pressure control valve can help conserve water. By setting it to a lower flow rate, you can reduce the amount of water used per flush, contributing to environmental conservation efforts.

Flapper Valve Function

By regulating the water flow, the flapper valve controls the release of water from the toilet tank. This crucial component is responsible for maintaining the proper water level in the tank and ensuring efficient flushing.

To keep the flapper valve functioning effectively, regular maintenance is essential. Inspecting the flapper valve for any signs of wear or damage is important. If the flapper valve is cracked or deteriorated, it may need to be replaced.

To replace the flapper valve, turn off the water supply to the toilet and flush it to drain the tank. Then, detach the old flapper valve from the flush valve and install the new one. Finally, turn on the water supply and test the flapper valve for proper functioning.

Following these maintenance and replacement steps will help ensure the flapper valve operates efficiently.

Gravity-Assisted Flushing

The gravity-assisted flushing system in toilets uses the force of gravity to flush waste down the drain. This simple yet effective design relies on the principle that water flows downward due to its weight. Here is a breakdown of the components and mechanism involved in the gravity-assisted flushing system:

-

Toilet Tank Construction:

- The toilet tank is typically made of durable materials such as porcelain or ceramic.

- It is designed to hold a certain amount of water, usually around 1.6 gallons (6 liters), which is released during flushing.

- The tank is securely attached to the bowl and contains various components, including the flapper valve and the fill valve.

-

Flapper Valve:

- The flapper valve is a rubber or silicone seal that covers the flush valve opening at the bottom of the tank.

- When the toilet is flushed, a lever or button is pressed, lifting the flapper valve and allowing water to flow into the bowl.

-

Flushing Mechanism:

- As the water rushes into the bowl, it creates a siphoning effect, pulling waste and wastewater from the bowl and down the drain.

- The force of gravity ensures that the waste is carried away effectively, leaving the bowl clean and ready for the next use.

Understanding the Flapper

When it comes to understanding the flapper in a toilet tank, it is crucial to grasp its function and role in the flushing mechanism.

The flapper functions as a valve that controls the release of water from the tank into the toilet bowl during a flush.

It is essential for proper flapper maintenance to ensure a leak-free and efficient flushing system.

Some maintenance tips include regular inspection for wear and tear, cleaning the flapper and its surrounding area, and replacing it if necessary.

Flapper Function Explained

To understand how a toilet tank works, you need to know how the flapper functions. The flapper is a crucial component that controls the flow of water from the tank to the bowl.

Here is a breakdown of how the flapper works:

-

Flapper Replacement: Over time, flappers can wear out or become damaged, causing leaks and inefficiency. It is important to replace a faulty flapper promptly to ensure proper functioning of the toilet.

-

Flapper Types: There are different types of flappers available, including the traditional rubber flapper and the newer flappers made of materials like silicone. Each type has its own advantages and considerations.

-

Flapper Operation: When the toilet is flushed, the flapper lifts up, allowing water to flow from the tank to the bowl. Once the tank is empty, the flapper closes, sealing the tank and stopping the water flow.

Understanding the flapper function is essential for maintaining a properly working toilet. By learning about flapper replacement and the different flapper types, you can ensure efficient water usage and prevent leaks.

Now, let’s move on to some useful flapper maintenance tips.

Flapper Maintenance Tips

Now that we understand how the flapper functions, let’s move on to some essential maintenance tips for ensuring its proper operation.

One common issue with flappers is wear and tear, which can lead to water leakage. If you notice any leaks from the tank, it might be time for a flapper replacement. This process involves shutting off the water supply, removing the old flapper, and installing a new one.

Additionally, it’s important to periodically check the flapper chain for proper adjustment. If the chain is too loose, it may prevent the flapper from fully sealing the tank, causing water wastage. On the other hand, if the chain is too tight, it may prevent the flapper from closing properly, resulting in constant water flow.

Therefore, adjusting the flapper chain to an optimal length is crucial for efficient toilet operation.

The Role of the Float and Float Valve

The float and float valve are essential components in the functioning of a toilet tank. The float mechanism helps regulate the water level in the tank, preventing it from overflowing.

Here’s how it works:

-

Float: The float is a hollow, buoyant object that floats on the surface of the water in the tank. When the water level rises, the float also rises, and when it reaches a certain height, it triggers the float valve to close.

-

Float valve: The float valve is connected to the float and controls the flow of water into the tank. When the float rises to the designated level, the valve shuts off, stopping the water supply. If the water level drops, the float also drops, and the valve opens to allow water to refill the tank.

-

Preventing overflow: The float and float valve work together to prevent the toilet tank from overflowing. When the tank is full, the float valve shuts off the water supply, ensuring that the water level remains at an optimal level.

Overall, the float mechanism plays a crucial role in maintaining the proper water level in a toilet tank and preventing any potential overflow.

Flushing Power and Pressure

The flushing power and pressure of a toilet are determined by several factors, including the design of the bowl and the force of the water. When it comes to toilet tank design, manufacturers use different techniques to optimize flushing efficiency. They incorporate advanced flushing technology to ensure a strong and effective flush every time. This technology includes features like larger trapways, improved bowl shape, and enhanced water flow. The table below outlines some common toilet tank designs and their corresponding flushing technologies:

| Toilet Tank Design | Flushing Technology |

|---|---|

| Gravity flush | Siphoning action |

| Pressure-assisted | Compressed air |

| Dual flush | Variable water volume |

These designs and technologies work together to create the necessary force and pressure to remove waste efficiently. Whether it’s a gravity flush, pressure-assisted, or dual flush system, the goal is to achieve a powerful flush while conserving water. Manufacturers continue to innovate and improve toilet tank design to provide even better flushing power and pressure.

Maintenance and Troubleshooting Tips

To ensure your toilet continues to work properly, it’s important to regularly maintain and troubleshoot any issues that may arise.

Here are some tips for maintaining and troubleshooting your toilet tank:

-

Toilet Tank Cleaning: Regularly clean the inside of your toilet tank to prevent buildup of mineral deposits and bacteria. Use a mixture of water and vinegar to scrub the tank, and make sure to remove any debris or sediment.

-

Water Level Adjustment: If your toilet tank is constantly running, check the water level. Adjust the water level by adjusting the float or fill valve to ensure it is at the proper level.

-

Replacing Worn Parts: Over time, parts inside the toilet tank may become worn or damaged. Check for any leaks or cracks in the tank, as well as any faulty valves or flappers. Replace these parts as needed to maintain proper functionality.

Frequently Asked Questions

Can I Use a Toilet Tank Without a Fill Valve?

No, you cannot use a toilet tank without a fill valve. The fill valve is responsible for refilling the tank with water after each flush. Without it, you would not have a source of water for the toilet tank to function properly.

Why Does My Toilet Tank Make a Hissing Sound After Flushing?

Why is my toilet tank making a hissing sound? To troubleshoot the issue, start with basic toilet tank maintenance. Check the fill valve, flapper, and water level. Adjust or replace any faulty components to resolve the hissing sound.

How Can I Increase the Flushing Power of My Toilet Tank?

To increase the flushing power of your toilet tank, consider increasing the water pressure by adjusting the fill valve or installing a pressure-assist flush system. Regular toilet tank maintenance, such as cleaning and checking for leaks, can also help maintain optimal flushing performance.

What Should I Do if My Toilet Tank Keeps Running Continuously?

If my toilet tank keeps running continuously, I would troubleshoot the issue by checking the flapper valve, adjusting the water level, or replacing the fill valve. Fixing toilet tank overflow ensures efficient water usage.

Is It Normal for the Water Level in a Toilet Tank to Fluctuate?

It is not normal for the water level in a toilet tank to fluctuate. If this is happening, it could be a sign of a problem with the fill valve or the flapper valve. Toilet tank maintenance and troubleshooting can help resolve this issue.

Conclusion

In conclusion, understanding how a toilet tank works is essential for maintaining a properly functioning bathroom fixture. The components, such as the water supply and fill valve, flushing mechanism, flapper, float, and float valve, all work together seamlessly to ensure efficient flushing power and pressure.

Regular maintenance and troubleshooting can prevent common issues like clogs and leaks. So next time you use the toilet, take a moment to appreciate the intricate workings behind the scenes, silently ensuring the convenience and comfort we often take for granted.