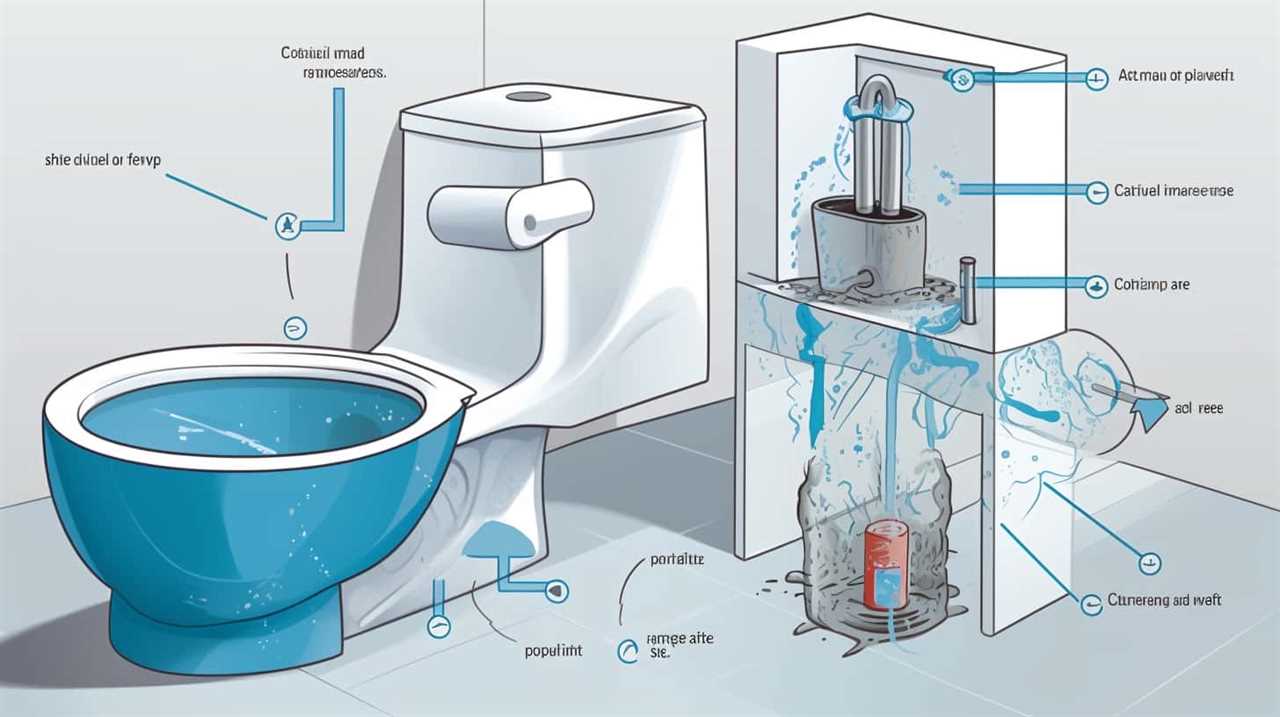

Have you ever wondered about the pressure on a Sloan flush valve? Understanding this crucial aspect is essential for maintaining optimal performance in your plumbing system.

In this article, we will delve into the factors that affect Sloan flush valve pressure, the recommended pressure range, and even provide troubleshooting tips for common pressure issues.

So, join us as we unravel the mysteries behind the pressure on a Sloan flush valve and empower yourself with the knowledge to achieve mastery in your plumbing endeavors.

Key Takeaways

- Proper maintenance and understanding of flush valve pressure is crucial for performance and longevity.

- Water supply pressure, valve size and design, and flapper condition all affect flush valve pressure.

- The recommended pressure range for Sloan flush valves is between 25 and 80 psi for optimal performance and efficiency.

- Measuring and adjusting the pressure on a Sloan flush valve can be done by attaching a pressure gauge and using the adjustment screw.

WITMYA Smart Toilet with Bidet Built In, One Piece Bidet Toilet with Auto Dual Flush, Foam Shield, Modern Elongated Tankless Toilet with Foot Sensor, Heated Bidet Seat, Warm Water & Dryer,LED Display

【Efficient Flush & Energy-Saving Design】There smart toilets feature a highly efficient 1.28 GPF water-saving dual flush system with...

As an affiliate, we earn on qualifying purchases.

Importance of Understanding Flush Valve Pressure

Understanding flush valve pressure is crucial for proper functioning and maintenance of Sloan flush valves. The importance of proper maintenance can’t be overstated when it comes to flush valves.

One key aspect of maintenance is monitoring and controlling the pressure exerted by the valve. High pressure can pose potential dangers to the system and the surrounding infrastructure. Excessive pressure can lead to leaks, valve malfunctions, and even damage to pipes and fixtures.

By understanding and regulating the pressure on the flush valve, you can ensure its optimal performance and prevent costly repairs. Regular inspections, adjustments, and maintenance procedures should be conducted to maintain the desired pressure levels.

This knowledge and attention to detail are essential for maintaining the longevity and efficiency of Sloan flush valves.

Smart Toilet with Bidet Built In, Heated Seat, Warm Water Wash & Dryer, Tankless Bidet Toilet with Foot Sensor & Night Light, Auto Open/Close Lid & Flush, Wireless Remote, 1.26GPF Water-Saving Design

🛠️ Easy Installation & Reliable Support: This smart toilet with bidet built in includes all accessories, flange kit,...

As an affiliate, we earn on qualifying purchases.

Factors Affecting Sloan Flush Valve Pressure

To properly understand the pressure on a Sloan flush valve, it’s important to consider the various factors that can influence it.

- Water supply pressure: The pressure of the water supply directly affects the pressure on the flush valve. Higher water supply pressure can result in increased flush valve pressure.

- Valve size and design: The size and design of the flush valve can impact the pressure. Different valve sizes and designs have varying pressure requirements for optimal performance.

- Flapper condition: The condition of the flapper, which controls the flow of water, affects the pressure. A worn or damaged flapper may result in lower pressure.

- Flush valve maintenance: Regular maintenance, including cleaning and lubricating the valve, is crucial for maintaining proper pressure. Neglecting maintenance can lead to decreased pressure and potential valve malfunction.

Adjusting flush valve pressure requires careful consideration of these factors. By understanding and addressing them, you can ensure optimal pressure and performance of your Sloan flush valve.

HOROW T38 Artistic Smart Toilet, Bidet Toilet with Powerful Flush, Auto Open/Close Lid, Instant Warm Water, Elongated Heated Seat, Dryer, Night Light, Deodorization

For Low Water Pressure: Smart toilet built-in water tank and pump bring efficient and powerful flushing performance. The...

As an affiliate, we earn on qualifying purchases.

Recommended Pressure Range for Sloan Flush Valves

Our recommended pressure range for Sloan flush valves is between 25 and 80 pounds per square inch (psi). This range has been determined through extensive testing and analysis to ensure optimal performance and efficiency. Operating within this recommended pressure range allows the valve to function at its best, delivering consistent and powerful flushes while minimizing water consumption.

Pressure below 25 psi may result in weak flushes and incomplete clearing of the bowl, while pressure above 80 psi may cause excessive force and potential damage to the valve components. It’s essential to maintain the pressure within this optimal range to ensure the longevity and reliability of your Sloan flush valve.

Now that we understand the recommended pressure range, let’s move on to the next section and learn how to measure the pressure on a Sloan flush valve.

Loniko Smart Toilet with Bidet Built In, Heated Seat & Dual Auto Flush, Foot Sensor, Tankless Modern Elongated Electric Toilet with Warm Water Wash, Air Dryer, LED Display & 1000g MaP Flush, 1.28 GPF

🧻 [Powerful & Water-Saving Dual Flush System] This one piece smart toilet with bidet built in uses an...

As an affiliate, we earn on qualifying purchases.

How to Measure the Pressure on a Sloan Flush Valve

Measuring the pressure on a Sloan flush valve involves assessing the water pressure within the recommended range of 25 to 80 psi. To ensure measuring accuracy and make necessary pressure adjustments, follow these steps:

- Use a pressure gauge: Attach a pressure gauge to the water supply line connected to the flush valve. This gauge will accurately measure the water pressure.

- Locate the pressure adjustment screw: On the Sloan flush valve, find the pressure adjustment screw. This screw allows you to increase or decrease the pressure as needed.

- Monitor the gauge reading: Turn on the water supply and observe the pressure gauge reading. Adjust the pressure using the adjustment screw until it falls within the recommended range.

- Test the flush valve: Once the pressure is adjusted, test the flush valve to ensure proper functioning.

Troubleshooting Common Pressure Issues With Sloan Flush Valves

Continuing the discussion on troubleshooting common pressure issues with Sloan flush valves, we can address potential solutions to ensure optimal performance. When faced with pressure problems, it is important to identify the root cause in order to apply the appropriate troubleshooting tips. Some common problems include low water pressure, valve not closing properly, or inconsistent flush. To help diagnose and resolve these issues, refer to the table below:

| Common Problem | Troubleshooting Tips |

|---|---|

| Low water pressure | Check water supply line, clean or replace strainer |

| Valve not closing properly | Inspect diaphragm, clean or replace if necessary |

| Inconsistent flush | Adjust flush volume control, check for blockages |

Frequently Asked Questions

Can the Pressure on a Sloan Flush Valve Be Adjusted?

Yes, we can adjust the pressure on a Sloan flush valve. By adjusting the water supply line, we can achieve the optimal pressure for efficient flushing. It is important to find the right balance for optimal performance.

What Happens if the Pressure on a Sloan Flush Valve Is Too High?

If the pressure on a Sloan flush valve is too high, it can negatively impact its performance. Pressure regulation is crucial to ensure proper functioning and prevent any potential damage to the valve.

Is It Possible for the Pressure on a Sloan Flush Valve to Fluctuate?

Yes, the pressure on a Sloan flush valve can fluctuate. This is due to the pressure regulation mechanism in the valve, which allows for adjustments to be made based on the specific needs of the system.

Can Using a Different Type of Flush Valve Affect the Pressure in a Sloan Flush Valve System?

Using a different flush valve type can impact the pressure in a Sloan flush valve system. Factors such as flow rate and valve design can affect the overall pressure within the system.

Are There Any Safety Concerns Related to the Pressure on a Sloan Flush Valve?

There may be safety concerns related to the pressure on a Sloan flush valve. It is important to properly adjust the pressure to ensure that the system operates correctly and avoids any potential issues.

Conclusion

Understanding the pressure on a Sloan flush valve is crucial for maintaining optimal performance. Factors such as water supply, valve settings, and piping can affect this pressure.

It’s recommended to maintain a pressure range of 25-80 psi for Sloan flush valves. Measuring the pressure accurately ensures proper functioning and avoids common pressure issues.

By troubleshooting and addressing any pressure problems promptly, you can ensure a smooth and efficient flush every time.